The liquid hold-up is lower in a packed column than a plate column. This is converted to m 3s as follows.

Distillation Column Design Check Epic Modular Process

Draw the operating line for the enriching section.

. The recommended practice for packed column design is dependent on the purpose for which the design is required. Number of theoretical stages. Relatively simple correlations of the important variables associated with allowable vapour rates in packed columns are presented.

The flow can be counter-current. Contact Koch Modular For A Quote. Series of equilibrium flashes with two feeds and two product streams Exiting liquid is at bubble point.

Use McCabe Thiele Given x. Characteristics of a packed distillation column for on-farm ethanol production Characteristics of a packed distillation column for on-farm ethanol production. 27 stages exclude condenser but include reboiler feed point location.

Experts At Custom Distillation. Height of column is 1272 m 13 m Dia meter of column is 119 m Packing is ceramic super intallox and height of each packing is 071 m 07 m with voidage of 20 Dia. Contact Koch Modular For A Quote.

Select the type and size of packing. D A rough column sizing is usually all that is needed for initial flowsheeting. The design procedure of a packed column consists of the following steps.

However in some gas-absorption columns co-current flow is used. 340 14 Examples for the design of packed columns Yo mYXXo-Y0 14-13 Yu mYXXu-Yu 14-14 The corresponding equations for the liquid phase are xu 1 mYX 1 mYX Yo Yu 14-16 14. 17 critical questions and answers about tray column internals and accessories by FWG Bulletin 674 Design of Skirt height for tall towers under high wind loading Tall Tower Design -.

Detailed design and rating calculations are required in the following circumstances. DÎcalculate RR trays Feed tray D B ÆDesign Given x. Feed condition Limit of q-value cold feed below bubble point q 1 feed at bubble point saturated liquid q 1 feed as partially vaporized 0 q 1 feed at dew point saturated vapor.

Determine the column height required for the specified separation. For corrosive liquids a packed column will usually be cheaper than the equivalent plate column. A column sizing to determine diameter and height prior to enquiry on.

Fq-1 5 Upper Operating Line 3. First find the desired top product composition on the x-axis and locate the. M3s kmolhr x mol wtdensity x.

These are similar to those already used for the. Packed Distillation Column Design Calculation Xls Keywords. The PackCol program performs hydraulic design and rating calculations for packed columns and towers.

Packed Distillation Column Design Calculation Xls Author. R 113 1 Average molecular weight of feed 046 x 3204 054 x 18 kg 2446 kmol 2 Molar Feed Flow Rate F kg kmol 25000 hr. This chapter deals with column packing effici ency considering the main studies including random and structured packing columns.

ChE 4253 - Design I. Column Diameter The vapour flow rate in either section of the column is obtained from the mass balance in kmolhr. In packed columns mass transfer.

Packed columns tend to be used for distillation gas absorption and liquid-liquid flow. A distillation column is a. Ad Koch Modular Engineers Excel At Tackling And Solving The Toughest Separation Problems.

Ad Koch Modular Engineers Excel At Tackling And Solving The Toughest Separation Problems. Compositions obey the equation. There r 13 stages above feed.

DESIGN CALCULATIONS RMIN 075. Exiting vapor is at dew point. Experts At Custom Distillation.

The design basis for new columns can be approach to flood.

Very Detailed Book Into Distillation Gas Absorption Etc

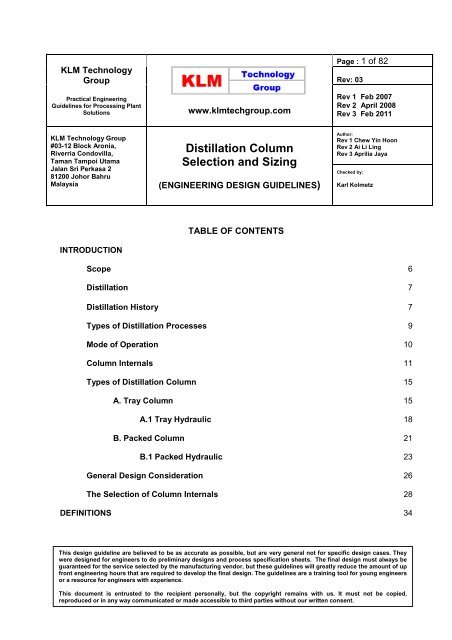

Distillation Column Selection And Sizing Klm Technology Group

Distillation Column Sizing Internals And Packing Using Aspen Plus Lecture 55 Youtube

0 comments

Post a Comment